Overview

Nanotechnology involves the manipulation of matter at nanometer scales to produce new materials, structures, and devices. Engineered nanomaterials (NM) are becoming more prevalent in research. One of the concerns of using nanoparticles/nanomaterials is that in some cases, very little is known about the physical toxicity of the nanoparticle/nanomaterial. Variances in size, shape, and surface area can affect toxicity at different levels. Materials that are normally considered non-toxic may be toxic at the nanosize regime. NM can enter the bloodstream via the skin or lungs and be retained in different organs. While there is still great uncertainty about toxicity profiles of engineered nanomaterials, there is enough circumstantial evidence to indicate that precautions should be taken.

For this reason, the safe science of NM use will be regularly monitored by Environmental Health and Safety (EHS). This document will be updated periodically to remain current on NM handling best practices.

Based on current knowledge and practices, NM should be treated as potentially hazardous unless it has been documented that exposure to the specific NM is not hazardous.

Regulations

At this time, there are no federal regulations that specifically address the health and safety implications of nanotechnology. There are also no national or international consensus standards on measurement techniques for nanomaterials in the workplace. However, as with conventional chemicals, research with nanomaterials must be conducted in a manner that is safe and responsible. All chemicals, including nanomaterials, must be transported, stored, used, and disposed in accordance with all federal, state, and local requirements.

The Occupational Safety and Health Administration (OSHA) require employers to maintain a safe and healthful workplace, “free from recognized hazards likely to cause death or serious physical harm” (29 USC 654). According to OSHA, laboratory personnel must be informed of the risks associated with workplace hazards. This is generally accomplished through training programs, material safety data sheets, labeling and signage.

The Resource Conservation and Recovery Act of 1976 (RCRA) regulates the transportation, treatment, disposal, and cleanup of hazardous waste. Nanomaterials that meet the definition of a “hazardous waste” in RCRA are subject to this rule.

Nanomaterials that are defined as “chemical substances” under the Toxic Substances Control Act (TSCA) and which are not on the TSCA inventory must be reported to U.S. Environmental Protection Agency (EPA). A Pre-manufacture notice must be submitted to the EPA by anyone intending to manufacture or import a chemical substance that is not on the TSCA inventory of chemical substances.

It should also be noted that the U.S. Food and Drug Administration currently regulates a wide range of products including those that utilize nanotechnology or that contain nanomaterials (e.g., a drug delivery device).

Risk Analysis/Assessment

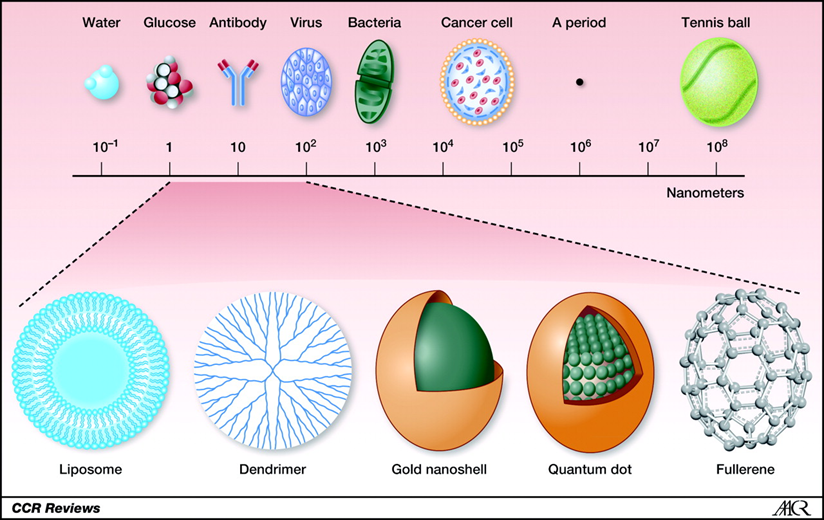

Research with nanomaterials has shown that the physico-chemical characteristics of nanoparticles can influence their effects in biological as well as non- biological systems. Some of these characteristics associated with nanomaterials include:

- Charge;

- Chemical reactivity;

- Degree of agglomeration;

- Shape;

- Size;

- Solubility;

- Surface area; and

- Surface composition.

There are many unknown as to whether the unique properties of engineered nanomaterials pose health concerns. The potential health risk following exposure to a substance is generally associated with the following (CDC/NIOSH, 2009):

- Magnitude and duration of the exposure;

- Persistence of the material in the body;

- Inherent toxicity of the material; and

- Susceptibility or health status of the person.

Unfortunately, there is limited data regarding the health risks related to nanomaterials. As such, this document is to provide EHS-accepted recommendations for practicing prudent health and safety measures when working with nanomaterials.

If Safety Data Sheet (SDS) information is available for nanomaterials it should be consulted to determine the material’s potential hazardous properties, Personal Protective Equipment (PPE), as well as its containment, handling and disposal. When a SDS is not available, the researcher should conduct a literature review to perform a risk analysis. If no information is available, the researcher should, at a minimum, use standard precautions described below for handling the material as if it were potentially hazardous. Part of the risk analysis/assessment should include:

- Assessment of the potential implications of human exposure to the NM being used recognizing that the characteristics of the NM are different from those of larger particles with the same chemical composition.

- Assessment of any potentially hazardous manipulations that increase the risk of human exposure such as cytotoxicity, aerosolization, injection, excretion, etc.

“The physicochemical characterizations of NM are important steps in toxicological and ecotoxicological studies in order to correctly evaluate and assess their potential exposure routes, toxicity, and related risk.” (Nanotoxicity, Monteiro-Riviere and Tran, 2007, p.19). Records of research use will ideally include the size, shape, surface area, chemical composition, lattice structure, surface charge, and aggregation state, as well as the makeup of any associated liquid media if supplied as suspension.

Mass, surface-area, and concentration remain important exposure metrics. Inter-disciplinary collaboration is essential to understanding and managing potential risk.

Researchers should develop their own standard operating procedures (SOP) based on their risk assessment and in consultation with this document and EHS. This standard operating procedure, when used in conjunction with completion of hazard communication training, should provide employees and students with an adequate “hazard communication” basis for use of engineered nanomaterials at UT Austin. In addition, the SOP should provide a detailed description of the procedures being conducted including the specific requirements for engineering controls, PPE, dosing, handling, bedding/cage changes, disposal, emergency response and occupational health.

Exposure Routes

The deposition of discrete nanomaterials in the respiratory tract is determined by the particle’s aerodynamic or thermodynamic diameter. Particles that are capable of being deposited in the gas exchange region of the lungs are considered respirable particles. Discrete and smaller nanomaterials are deposited in the lungs to a greater extent than larger respirable particles. Deposition increases with exertion (due to an increase in breathing rate and change from nasal to mouth breathing). It also increases among persons with existing lung diseases or conditions. Based on animal studies (Oberdorster), discrete nanomaterials may enter the bloodstream from the lungs and translocate to other organs. Because of their ultra-small size, nanoparticles can penetrate cell membranes and integrate themselves into larger molecules. They can resist cellular defense systems but are large enough to interfere with cell processes.

Ingestion is another route whereby nanomaterials may enter the body. Ingestion can occur from unintentional hand-to-mouth transfer of materials. This can occur with traditional materials and it is scientifically reasonable to assume that it could happen during handling of nanomaterials. This is specifically true while handling very high surface area (>20 m2/g), porous dry nanomaterials which includes metals, nonmetal oxides, or their mixed forms, and microporous or mesoporous metal organic framework. Some of the examples of commonly used materials of this category are CeO2, TiO2, SiO2, Co3O4, Mn3O4, Ru3O4, ZnO, OS3O4, V2O3, graphene, carbon nanotube and MgO. Ingestion may also accompany inhalation exposure because particles that are cleared from the respiratory tract via the mucociliary escalator may be swallowed.

A few studies (Murray, 2009, Wang et.al, 2011) suggest that nanomaterials may enter the body through the skin during exposure. At this time, little is known if skin penetration of nanomaterials would result in adverse health effects. There is also little information about the health effects of injecting nanomaterials into living organisms.

Potential Sources of Occupational Exposure to Nanomaterials for Various Synthesis Methods | |||

Process Synthesis | Particle Formation | Exposure Source or Worker Activity | Primary Exposure Route** |

Gas Phase | In Air | Direct leakage from reactor, especially if the reactor is operated at positive pressure | Inhalation |

Product recovery from bag filters in reactors. | Inhalation/Dermal | ||

Processing and packaging of dry powder. | Inhalation/Dermal | ||

Equipment cleaning/maintenance (including reactor evacuation and spent filters). | Dermal (and inhalation during reactor evacuation) | ||

Vapor Deposition | On Substrate | Product recovery from reactor/dry contamination of workplace. | Inhalation |

Processing and packaging of dry powder. | Inhalation/Dermal | ||

Equipment cleaning/maintenance (including reactor evacuation). | Dermal (and inhalation during reactor evacuation) | ||

Colloidal | Liquid Suspension | If liquid suspension is processed into a powder, potential exposure during spray drying to create a powder, and the processing and packaging of the dry powder. | Inhalation/Dermal |

Equipment cleaning/maintenance. | Dermal | ||

Attrition | Liquid Suspension | If liquid suspension is processed into a powder, potential exposure during spray drying to create a powder, and the processing and packaging of the dry powder. | Dermal |

Equipment cleaning/maintenance. | Dermal | ||

** Note: Ingestion would be a secondary route of exposure from all sources/activities from deposition of nanomaterials on food or subsequently swallowed (primary exposure route inhalation) and from hand-to-mouth contact (primary exposure route dermal). | |||

Table 1 – Sources of Exposure to Nanomaterials through Occupational Activities (Aiken et al. 2004)

Factors Affecting Exposure

Every attempt should be made to prevent or minimize exposure to nanomaterials. Factors affecting exposure to nanomaterials include the amount of material being used and whether it can be easily dispersed or form airborne sprays or droplets. The degree of containment and duration of use will also influence exposure. In the case of airborne material, particle or droplet size will determine whether the material can enter the respiratory tract and where it is most likely to deposit. Inhaled particles smaller than 10 micrometers in diameter have some probability of penetrating and being deposited in the gas-exchange (i.e., alveolar) region of the lungs, but there is at least a 50% probability that particles smaller than 4 micrometers in diameter will reach the gas-exchange region.

At present there is insufficient information to predict all of the situations and workplace scenarios that are likely to lead to exposure to nanomaterials. However, there are some workplace factors that will increase the potential for exposure, including (CDC/NIOSH, 2009): Working with nanomaterials in liquid media without adequate protection (e.g. gloves) will increase the risk of skin exposure.

- Working with nanomaterials in liquid media during pouring or mixing operations, or where a high degree of agitation is involved, will lead to an increased likelihood of inhalable and respirable droplets being formed.

- Generating nanomaterials in the gas phase in non-enclosed systems will increase the chances of aerosol release to the workplace.

- Handling nanopowders will lead to the possibility of aerosolization.

- Maintenance on equipment and processes used to produce or fabricate nanomaterials will pose a potential exposure risk to workers performing these tasks.

- Cleaning of dust collection systems used to capture nanomaterials will pose a potential for both skin and inhalation exposure.

Containment

The primary routes of exposure to NM are through the inhalation of airborne NM and dermal exposure; ingestion is a secondary route of exposure. The containment guidelines below are designed to help minimize a potential exposure through these routes.

The preferred method to minimize personnel exposure to liquid or matrix-bound NM is through engineering controls. Physical containment such as a fume hood, glove box, biological safety cabinet or downdraft table may be necessary to dose/handle animals and for changing bedding/cages. At a minimum, engineering controls should include local exhaust ventilation and localized filtration. Respiratory protection may be required when working with nanomaterials when local exhaust ventilation and filtration is not available.

The following engineering controls are recommended for the safe handling of nanomaterials (CDC/NIOSH, 2009; VCU, 2007):

Use of containment is recommended for all tasks with potential of aerosolizing nanomaterials in either liquid or powder form.

- A well-designed local exhaust ventilation system with a local high-efficiency particulate air (HEPA) filter should be used to effectively remove nanomaterials.

- If heavy usage of aerosolized nanoparticles is in use, a proper decontamination, or buffer area should be utilized to ensure the nanomaterials are not transported outside of the working area.

- Laboratories and other spaces where nanomaterials are used or stored must be equipped with an eyewash station that meets American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) requirements.

The second level of containment is through administrative controls. Employees are encouraged to use hand-washing facilities after removing PPE and before leaving the laboratory. Inadvertent contamination caused by the transfer of NM on clothing and skin can be reduced by training personnel to leave lab coats in the work area and provide laundry services for lab coats or implement disposable lab coats. In addition, it is important to incorporate the following administrative controls into all laboratory operations:

The laboratory’s safety plan should be modified to include health and safety considerations of nanomaterials used in the laboratory.

- Principal investigators should develop and implement standard operating procedures (SOPs) in the preparation and administration of nanomaterials (with minimal exposure).

- Protocols involving the in vivo use of nanomaterials must be reviewed and approved by the Institutional Animal Care and Use Committee (IACUC).

- Laboratory personnel must receive the appropriate training, including specific nanomaterial-related health and safety risks, standard operating procedures, and steps to be taken in event of an exposure or unintended release incident, prior to working with nanomaterials.

- Laboratory personnel must be instructed to use extreme caution when performing injections involving nanomaterials since accidental needle stick presents an exposure threat.

- Exposures involving nanomaterials or any other acutely hazardous material must be reported to the Environmental Health and Safety Department as soon as possible.

- Animals should be appropriately restrained and/or sedated prior to administering injections and other dosing methods.

- Frequent hand washing, especially before eating, smoking, applying cosmetics, or leaving the work area should be employed.

If engineering or administrative controls do not eliminate the exposure potential, use of personal protective equipment is indicated. The minimum PPE for working with potentially hazardous NM are gloves, a lab coat, and eye protection. Open–toed shoes, shorts, skirts, and cuffed pants are prohibited. Glove selection is best determined by a risk assessment and the chemicals used for the procedure. Nitrile or rubber gloves, which cover hands and wrists completely through overlapping sleeve of lab coat when working with nanomaterials, may provide adequate protection. Wearing of two sets of gloves “double gloving” is advised whenever performing tasks involving nanomaterials and other hazardous substances. Laboratory personnel should thoroughly wash hands with soap and water immediately upon removal of gloves.

Additional PPE may be necessary as determined by the risk assessment. Safety glasses or goggles are considered to be the appropriate level of eye protection for working with nanomaterials. EHS recommends wearing a full-face shield when conducting tasks posing potential for any generation of aerosol and/or droplets. A respirator may be needed if working with high surface area mesoporous/ microporous powders or aerosols outside of a glove box or fume hood. When working with nanomaterials, one of the following types of NIOSH-approved respirators may be needed:

- Filtering face piece (N-95 or greater)

- Elastomeric half- or full-face piece with N-100, R-100, or P-100 filters; or

- Powered air-purifying respirator with N-100, R-100, or P-100 filters.

If a respirator is advised based on the researcher’s risk assessment and/or an EHS risk assessment, contact the Occupational Health Program to schedule annually required respiratory medical clearance and fit testing. If a respirator is advised then dust or surgical masks should not be used in place of NIOSH-approved respirators for protection against NM

Using Nanomaterials with Animals

Dosing animals with nanoparticles related processes/procedures

- Dosage preparation should not be done in animal rooms or in multi-user rooms. Dosage preparation should be done in the PI’s lab. Unused materials should be returned to the PI’s lab.

- Only essential personnel should be in the room during dosing. The room should be secured.

- Animals should be chemically or physically restrained during dosing.

- Work areas should be cleaned up and decontaminated after animal dosing is completed.

- Animals should be dosed in containment and absorbent paper used to contain small spills, syringe leakage, etc. Absorbent paper should be changed after each experiment and disposed as nanoparticles waste.

- Luer-lock syringes should be used to prevent needle “blow-off”.

- If preparation is being administered via a syringe or other feeding device, a fume hood or BSC must be used. If administration is by food, use of a micro-isolator cage is recommended.

Handling Animals

If NM is expected to be shed by the animals, PPE should be worn when handling the animals. If the potential exists for the excreted NM to be aerosolized during handling, then the animals should be manipulated in ventilated containment (fume hood/BSC).

Bedding/Cage Changes

- Use of disposable cages after inoculating mice with NM is recommended. Cage cards should indicate animals have been inoculated in addition to the estimated washout period. Animals should be kept on a dedicated rack.

- If metabolic cages are used, use ventilated containment (BSC or fume hood) for handling waste containers and cleaning of cage components.

- Personnel should wear proper PPE (gloves, lab coats, respirator, and eyewear) during cage changes to reduce exposure.

- Once inoculated, NM may be excreted into the bedding. Waste/bedding/disposable cages should be disposed in appropriate containers by trained staff.

- Cage changes should not be performed for the first 72 hours.

- Animals can typically be transferred to standard micro-isolator cages after 72 hours.

- Cage changes/dumping may need to be conducted in containment (BSC) based on the risk assessment.

Transportation

Caution should be taken when transporting animals dosed with NM. To reduce the potential for exposure to the transporter/driver, dosed animals should typically not be transported until they have been transferred to a clean cage (for at least 72 hours after dosing). Consideration should be given to first transporting the animals to the new location before dosing them.

NM Waste Disposal

Nanomaterial waste includes:

- Pure nanomaterial

- Anything contaminated with nanomaterial like PPE, wipes etc.

- Colloid or a suspension of nanomaterial

- Solid matrix or animal carcass injected with nanomaterials

- Nanomaterial deposit on a substrate

- Equipment contaminated with nanomaterials

Characterize and manage nanomaterial waste according to federal and state regulation as well as institutional policies. Package nanomaterial waste in containers compatible with the contents and make sure the containers afford adequate containment to prevent the release or escape of nanomaterials.

Nanomaterials are used in a wide variety of fields and waste can be generated in various places including research labs, teaching labs and clinics. It is always the best practice to have exact labeling and proper storage of nanowaste.

Paper, wipes, PPE and other items with loose contamination are collected in a plastic bag or other sealable container and then stored in a laboratory hood. When the bag is full, close it, and place it into a second plastic bag or other sealable container. Label the outer bag with the appropriate EHS hazardous waste tag to indicate specifically which nanomaterials it contains. Label the waste container with a description of the waste and the words “Contains Nanomaterial”. For example, if it is cadmium selenide waste it would be labeled as “nano-cadmium selenide waste.” Nanomaterial-related waste should not be put into the regular trash or down the drain. Equipment used to manufacture or handle nanomaterials should be decontaminated before it is disposed of or reused. Waste should be managed in such a way that minimizes exposure of those handling the waste to the nanomaterial component, including via the use of containment and (disposable) protective clothing.

Information relating to the hazardous properties of the material to be disposed of should be communicated to the EHS hazardous materials disposal program.

Ventilation Requirement for Nanomaterials

All laboratory operations and procedures should be conducted in such a way that minimizes the risk of exposure to nanomaterials from inhalation or contact. Handling nanomaterials in dry and powder form is always challenging and poses the greatest risk of exposure. This is also valid for dry-powder, very high surface area metal organic frame-work (MOF) or nanomaterials incorporated MOF. Therefore, all the procedures that involve easily dispersible dry nanomaterials or matrix require more attention and effective controls. Some of the very high surface area nanomaterials (examples: high surface area mesoporous graphitic carbon, graphene, carbon nanotube, mesoporous titanium dioxide, magnesium oxides, cobalt oxides, iron oxides, manganese oxides, fine metal powders etc.) are incredibly easy to disperse in air; because of this, open/transfer sample vials or containers of nanomaterial on the bench top should be strictly avoided. This is especially applicable for laboratories in which bench top height is set to a similar level as the breathing zone of lab workers. Many of the fine nanosize metal powder particles are pyrophoric and spontaneously ignite in air (for example, pure nanosize iron, rhodium, palladium, platinum, magnesium, zinc, calcium etc.). Opening/transfer of these pyrophoric nanomaterials should be carried out strictly in a glove box. Always use appropriate respiratory protection while handling nanomaterials outside an enclosure.

Any procedure that potentially generates nanoparticles should be conducted in an enclosure that operates at a negative pressure differential compared to a worker’s breathing zone. Types of appropriate enclosures includes glove boxes, glove bags, and chemical fume hoods. If a process or a subset of a process cannot be enclosed, then it is highly recommended to use other engineered systems to control the emissions of nanomaterials such as a snorkel. All work with nanomaterials should be carried out in the most appropriate available contaminant-controlled system. Solid nanomaterials with a high surface area are always challenging to handle.If it is not feasible to handle these spontaneously dispersible, high surface area, solid nanomaterials in regular containment systems then conduct and document the results of a hazard analysis before using alternative hazards control.

The effluent from the ventilated enclosures should be exhausted outside the building. Filters, scrubbers, or bubblers may help to reduce the emission of nanomaterials. The pore dimension of commercially available filters may be higher than the actual nanomaterial pore dimensions. Therefore, it is recommended to select a filter based on the nature and size of the nanomaterial.

Nanomaterial use in horizontal laminar-flow hoods is not recommended because it matches the breathing zone of the lab workers. Air from inside the nanomaterial-containing enclosures (including biosafety cabinets) should not be recirculated within the laboratory even if the enclosures air is HEPA-filtered except as outlined in ANSI/AIHA Z 9.7-2007. Always maintain and test the effectiveness of exhaust systems and components as specified by the manufacturer. Evaluate the current status of the equipment previously used to synthesize, characterize, handle or capture nanomaterial for contamination and incompatibility before relocating.

EHS prohibits laboratory personnel from designing their own ventilation system or modifying an existing system.

Training and Documentation

Personnel should be trained on the potential hazards of working with NM as part of their site-specific hazard communication training. An SOP should be developed and submitted to EHS for review. Review of SOPs should be documented for all personnel who handle NM.

Researchers submitting protocols to the IACUC should note the NM they are planning to use in the toxic/hazardous substance section of the protocol application.

Emergency Response

Report any spills to the PI and EHS.

Spills

- If a spill is minor and known limited danger, clean up immediately wearing PPE.

- Standard approaches for cleaning powder spills include using HEPA-filtered vacuum cleaners, or wiping up the powder using damp cloths or wetting the powder prior to dry wiping. Damp cleaning methods are preferred. Liquid spills may be cleaned by applying absorbent materials. At a minimum, the following procedures must be followed when managing an accidental spill of nanomaterials (CDC/NIOSH, 2009):

-Small spills (typically involving less than 5 mg of material) of nanomaterials containing powder should be wet-wiped with cloth/gauze that is dampened with soapy water. Affected surfaces should be thoroughly wet-wiped three times over with appropriate cleaning agent and with a clean, damp cloth used for each wipe down. Following completion, all cloth and other spill clean-up materials with a potential for nanomaterial contamination must be disposed of as hazardous waste.

-Small spills (typically involving less 5 ml of material) of nanomaterial-containing solutions should be covered and absorbed with absorbent material. Areas affected by liquid spills should be triple cleaned with soap and water following removal of absorbent paper.

- Use of commercially available microfiber cleaning cloths may also be effective in removing NM from surfaces with minimal dispersion into the air. Cleaning cloths should be properly disposed.

- If a spill is major or potentially dangerous, evacuate the area and call EHS 512-471-3511.

Exposures

- For dermal exposures to dry material, brush the material off the skin first with a gloved hand and paper towel or other assistive device, then wash the affected area for a minimum of 15 minutes with soap and water.

- For dermal exposures to liquid material, immediately rinse the affected area for a minimum of 15 minutes with soap and water.

- Remove any contaminated clothing and seal in a bag.

- In the event of inhalation exposure, immediately seek fresh air.

- In the event of eye contact, immediately flush eyes with water for at least 15 minutes.

- In the event of a needle stick, remove needle and wash affected area with soap and water.

- Contact Occupational Health at 512-471-4OHP(4647) for all exposure incidents. If an appointment with Occupational Health is required, bring the SDS (if available) or risk assessment information for the NM being used.

Occupational Health

Occupational Health should be consulted whenever a suspected or actual exposure to NM takes place. Personnel who work with NM in animals should notify Occupational Health that they are working with NM on their initial Occupational Health Risk Assessment form and update their NM information on subsequent health monitoring update forms. Personnel who indicate on their Occupational Health Risk Assessment form that they wear respiratory protection (N95 or higher) will be scheduled for annual respiratory medical clearance. Contact Occupational Health at 512-471-4OHP(4647) for all exposure incidents. If an appointment with Occupational Health is required, bring the SDS (if available) or risk assessment information for the NM being used

Glossary

Nanotechnology Definitions

To assist with consistent terminology involving nanotechnology, UT has adopted the definitions for nanomaterials from the International Organization for Standardization Technical Committee 229 (Nanotechnologies).

According to ISO/TS 27687:2008, a nano-object is defined as material with one, two, or three external dimensions in the size range from approximately 1–100 nm. Subcategories of nano-objects are:

- nanoplate, a nano-object with one external dimension at the nanoscale;

- nanofiber, a nano-object with two external dimensions at the nanoscale with a nanotube defined as a hollow nanofiber and a nanorod as a solid nanofiber; and

- nanoparticle, a nano-object with all three external dimensions at the nanoscale.

Nano-objects are commonly incorporated in a larger matrix or substrate referred to as a nanomaterial. Nano-objects may be suspended in a gas (as a nanoaerosol), suspended in a liquid (as a colloid or nanohydrosol), or embedded in a matrix (as a nanocomposite).

Additional definitions

Agglomerate – A group of particles held together by relatively weak forces, including van der Waals forces, electrostatic forces and surface tension.

Aggregate – A heterogeneous particle in which the various components are held together by relatively strong forces, and thus not easily broken apart.

Buckyballs - Spherical fullerenes composed entirely of carbon (C60).

Fullerenes - Molecules composed entirely of carbon, usually in the form of a hollow sphere, ellipsoid, or tube.

Graphene - A one-atom thick sheet monolayer of graphite.

Nanoscience – The study of phenomena and manipulation of materials at atomic, molecular and micromolecular scales, where properties differ significantly from those at a bulk scale.

Nanoaerosol – A collection of nanomaterials suspended in a gas.

Nanocolloid – A nanomaterial suspended in a gel or other semi-solid substance.

Nanocomposite – A solid material composed of two or more nanomaterials phase having different physical characteristics.

Nanoparticle – A substance with dimensions less than 100 nanometers in size.

Nanohydrosol – A nanomaterial suspended in a solution.

Nanotechnology – The understanding and control of matter at dimensions of roughly 1 to 100 nanometers, where unique phenomena enable novel applications.

Nanotubes - A sheet of graphene rolled up into a seamless cylinder with diameter on the order of a nanometer.

Nanowires - A wire of dimensions on the order of a nanometer.

Nucleation - The first step of the growth mechanism of nanomaterials during synthesis in which tiny atom/molecules/ particles rearranged to form a bigger or smaller particles with different/same geometry

Physicochemical – The underlying molecular organization of life that is manifested as chemical and energy transformations.

Pyrolysis - Chemical change brought about by the action of heat.

Quantum Dots – A nanomaterial that confines the motion of conduction band electrons, valence band holes, or excitons (pairs of conduction band electrons and valence band holes) in all three spatial directions.

Single-Walled Carbon Nanotube – A single sheet graphene wrapped into a tube approximately 1.5 nanometers in diameter.

Thermites – A mixture of aluminum powder and a metal oxide (as iron oxide) that when ignited evolves a great deal of heat and is used in welding and in incendiary bombs.

Translocation – The act, process, or an instance of changing location or position.

Transmission Electron Microscopy (TEM) – A microscopy technique whereby a beam of electrons is transmitted through an ultrathin specimen, interacting with the specimen as it passes through, and produces an image formed from the interaction of the electrons transmitted through the specimen which is then magnified and focused onto an imaging device.

Ultra-Fine Particles - Airborne particles with an aerodynamic diameter of 0.1 m (100 nm) or less.

References

NIOSH Publication No. 2009-125: Approaches to Safe Nanotechnology

Managing the Health and Safety Concerns Associated with Engineered Nanomaterials

NIOSH Publication No. 2009-116: Current Intelligence Bulletin 60: Interim Guidance for Medical Screening and Hazard Surveillance for Workers Potentially Exposed to Engineered Nanoparticles

NIOSH Publication No. 2008-112: Safe Nanotechnology in the Workplace

Interim Best Practices for Working with Nanoparticles Center for High-Rate Nanomanufacturing. M. Ellenbecker Revision 0 – November 2007

Aitken, R.J., Creely, K.S., Tran, C.L. Nanoparticles: An Occupational Hygiene Review. Research Report 274. Prepared by the Institute of Occupational Medicine for the Health and Safety Executive, North Riccarton, Edinburgh, England. 2004.

Nanotechnology and Nanoparticles – Safe Working Practices Information. Virginia Commonwealth University. Office of Environmental Health and Safety. 2007

Occupational Safety and Health Act of 1970 (29 U.S.C. 654). Section 5(a) (1).

Nanoparticles Safety Guide, The University of Texas Health Science Center at Houston, Safety, Health, Environment, and Risk Management

ISO/TS 27687:2008, Nanotechnologies --Terminology and definitions for nano-objects -- Nanoparticle, nanofibre and nanoplate